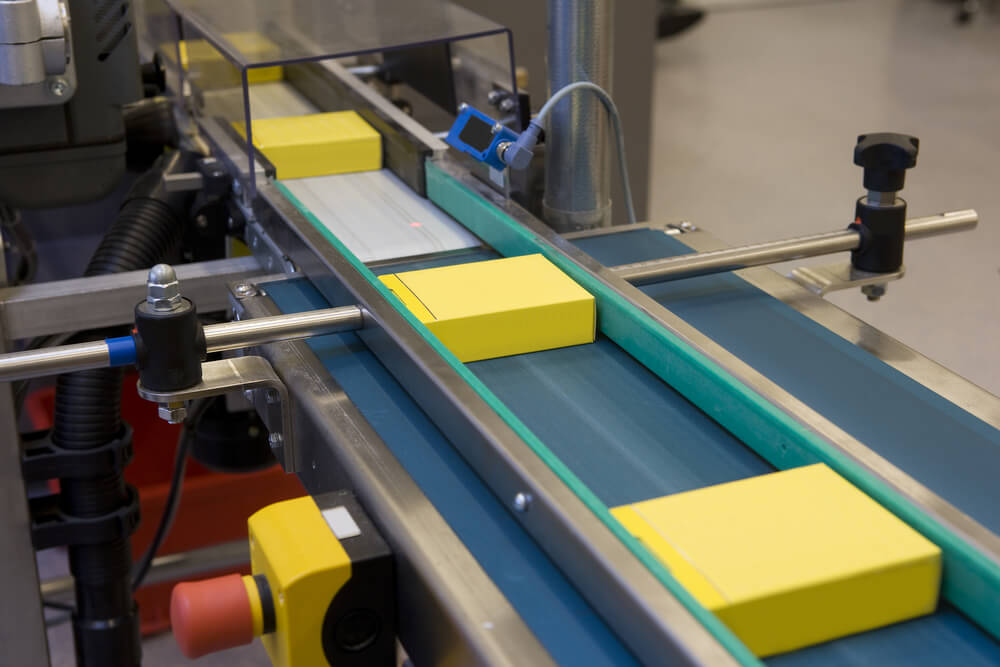

A conveyor is a piece of mechanical equipment that handles the task of moving a product from point A to point B. The technology behind it is pretty simple. However, choosing the right conveyor can present a challenge. The wrong type of equipment will decrease your throughput, productivity, and as a result – your profits. We have put together the ultimate guide on conveyors that will help you make an informed decision.

This is by far the simplest type of conveyor that doesn’t require any forces but inertia and gravity to move the product forward. Non-powered conveyors can be used to load packages into the truck, take away the products coming out of a sorter or help employees push the goods to the next workstation. The two most common types of non-powered conveyors are skatewheel and roller. To choose the right conveyor type, remember the main difference between them:

There are a lot of different types of powered conveyors. The two most popular are belt and roller ones. Don’t know how to choose the right conveyor?

Another important factor is the size and weight of the product. Rollers are great at handling heavy packages, however, they won’t do a good job with small or super light objects that can fall between or off the rollers. In this case, it is better to use belt conveyors. They have rubber surface which can be ribbed to provide a better grip on incline or decline. When it comes to choosing the right conveyor rollers diameter, take the size of your product into consideration. There should always be at least three rollers per one item to make sure it has a smooth ride without any wobbling or gaps.

Still wondering how to choose the right conveyor belt? There is a lot more to it than just selecting the type:

Before installing any conveyor, figure out the maintenance plan, and how much it will cost you to repair the system should it go down. Choose the right conveyor solution that is reliable and easy to maintain.

Last but not least, you should choose the right company to provide you with high-quality conveyor systems. Look for a partner that is:

Now you know how to choose the right conveyor. Invest in the best equipment and watch your profit skyrocket!